My introduction to gathering wild apples for profit began in the mid-1960s. Dad and I hunted every weekend for rabbits, squirrels, and partridge. These hunts took us across Weston, Mount Holly, and Shrewsbury.

In those days there were many abandoned farms, but by then most were just cellar holes. Apples were an excellent cash crop. Every farmer cultivated them. I have seen many ledger entries from the 1760s into the 1840s. Cider brandy was a hot commodity, and widely accepted as payment.

Many of these abandoned farms had a dozen or more old apple trees. As we looked for deer and bear sign under the trees, I noticed all the apples lying on the ground. It occurred to me that there might be a market for these apples. Sure enough, there was.

Dad always encouraged my business ventures. We carried in the Scout burlap bags and bushel baskets. When we were done hunting, I would fill bags or baskets with apples. Dad always pitched in to help. Where to sell them was the question.

Nelson Kendall

Nelson Kendall had a cider press in his central barn entry. When I had gathered up a few hundred pounds of apples, Dad would drive me to see Nelson. Dad didn’t interfere. Nelson and I made the deal. I always left with a little money and some cider for the family to enjoy.

One recent Sunday at Kendall church, the Kendall brothers told me about their father Nelson buying apples and pressing them. First the apples are ground and then pressed, under hydraulic pressure, to extract the juice. Some Weston boys brought Nelson apples for him to buy. Apples were weighed and bought by the pound.

The Weston boys added rocks to their bags of apples to increase the weight. You can imagine what would happen to the grinding mechanism when rocks were introduced. Many cider makers would have deservedly gone ballistic on the Weston boys. Nelson wasn’t a violent person, but he was very firm when the boys returned with apples. He made them dump their apples on the lawn and remove any rocks before he would buy them.

Bob Turco

Bob told me about his brother Mike and Jimmy Keith picking up apples along the road next to Marie Hill Farm. You may remember when there was a row of apple trees along the road at Marie Hill Farm. Bob said they sold their apples to Nelson and bought beer with their profit.

Wild apples

Wild apples are the key to the best cider, hard or sweet. These apples have not been sprayed with insecticides. They are smaller apples complete with warts. Warts will include worms insecticides would have killed in an apple orchard of today.

Today, a lot of cider is pasteurized before it hits your table. Cider from wild apples is a rarity today. This cider is not pasteurized, nor the apples washed before grinding. Orchard apples need to be washed before being ground to remove insecticides sprayed on them during the summer.

Ogden’s cider mill in Hartland

When Nelson sold his press in the late 60s, I took my apples to Ogden’s mill in Hartland to sell. I was somewhat intimidated by Ogden’s operation. It was larger and more commercial than Nelson’s. Remember, I’m just a teenager.

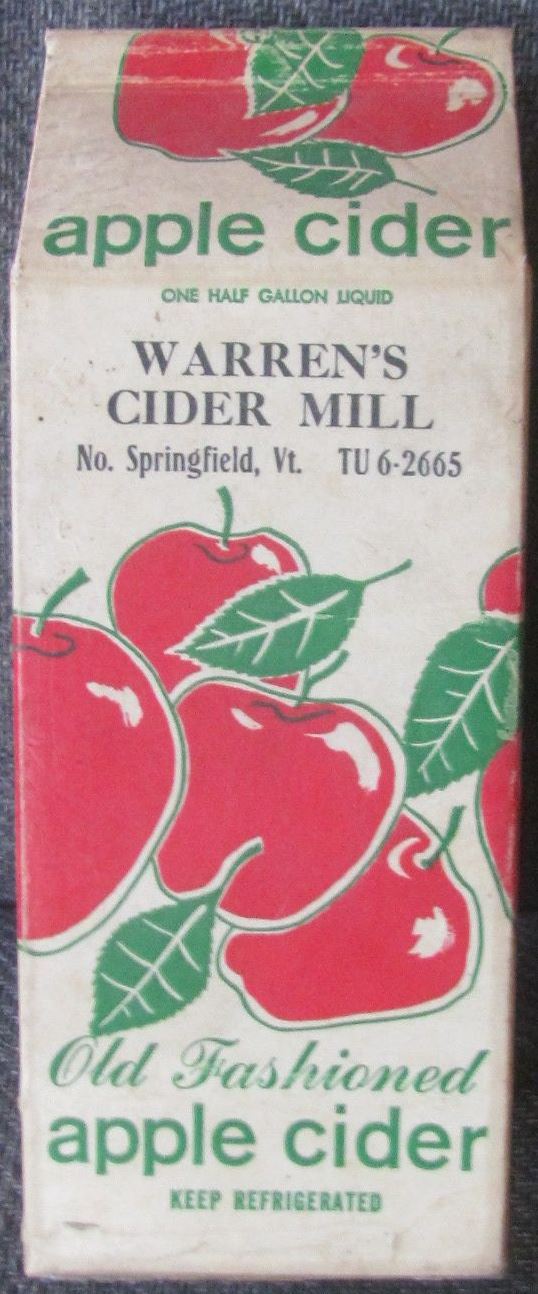

Jim Warren

Jim ran a cider mill in North Springfield. I don’t recall doing cider business with Jim, but I did sell him honey.

Willis Wood

Today, Willis Wood on the Weathersfield Center Road is grinding and pressing apples. He makes and sells a lot of cider jelly.

Willis makes about a thousand gallons of drinking cider. His major product is cider jelly. To make cider jelly, Willis uses 30,000 gallons of cider. He boils his cider on the same arch he uses for maple syrup, although different pans. Willis says it’s an 8-to-1 ratio. Eight gallons of cider will boil down to one gallon of cider jelly.

His cider press was built in 1882, and was run by water power. Today it uses an electric motor. Watching the gears and ratchets mesh is interesting for someone like me. Willis presses three times a day, each press producing about 200 gallons.

He’s open every day now until mid-November. He’s located on the Weathersfield Center Road. Stop by and see his operation. It’s a neat place.

This week’s old saying. “Even rarer than a doctor who can’t stand the sight of blood, is a lawyer who can’t stand the sight of money.”