Below is more of Ed Kendall’s 1958 Springfield Reporter story about Chester Soapstone. The previous article ended with, “The drivers had many hair raising moments driving down this hill with their heavy loads…”

“Two of these drivers stand out in my memory very clearly. I remember John Farmer, what pride he took in his horses. He had a daughter, Grace, who for a time was a schoolmate of mine, though some years younger. At the time I came to North Springfield, 55 years ago, Charles Cadwell had the job. Once in awhile these men would let a boy make the trip with them. A ride down that hill on the wagon with its heavy load was something a boy never would forget.

Little by little the demand for soapstone products became less and less. The nicely enameled sinks and tubs, made of iron, came into universal use. Electric heating pads took the place of the foot warmer. The soapstone stove, once so popular, is only a curiosity today. The stone griddle that cooked its cakes so nicely was put out of commission by electric utensils. About the only use made of this stone today is the dust usually sold under the name of ground talc.

For many years, the buildings in the mill yard in Chester have been vacant. I am told by one who is competent to judge, that there are several veins of excellent quality still to be found on the old quarry property, now covered with growing trees and brush…

Vast quantities of waste material soon accumulated at the mill, there was not the demand for ground talc that there is today. The manufacture of asphalt shingle was in its infancy.

In February, 1887, the Chester Steam Power Co. leased a parcel of land adjoining that leased to the Union Soapstone Co., to the National Soapstone Finish Co…

This company at once erected a building, installed a steam engine, equipped the building with powerful grinders or crushers, machines for sifting and bolting the dust, and mixers for mixing certain products, which I describe to the best of my memory.

Of course their first process was the grinding of the waste stone to a fine dust. This dust was sifted and bolted until a powder finer than the finest flour of today was produced. This powder was the chief ingredient of several products put out by the company. One of them was a finish for walls and ceilings. This finish, without the addition of coloring, produced a very soft blue gray wall or ceiling, durable, free from cracks, non-porous, and very sanitary. They also made it in colors, about any shade except green was obtainable…

Another product was a soapstone mortar, made in various colors, used in laying brick walls. For a while there was quite a demand for this material.

Probably their most important product was the Potter Blackboard Material. This could be applied directly to the plastered walls of school buildings. It was applied by a mason in the same manner he applied a skim coat of hard finish today. A blackboard of this material was nearly as satisfactory as slate blackboard found in our schools today…”

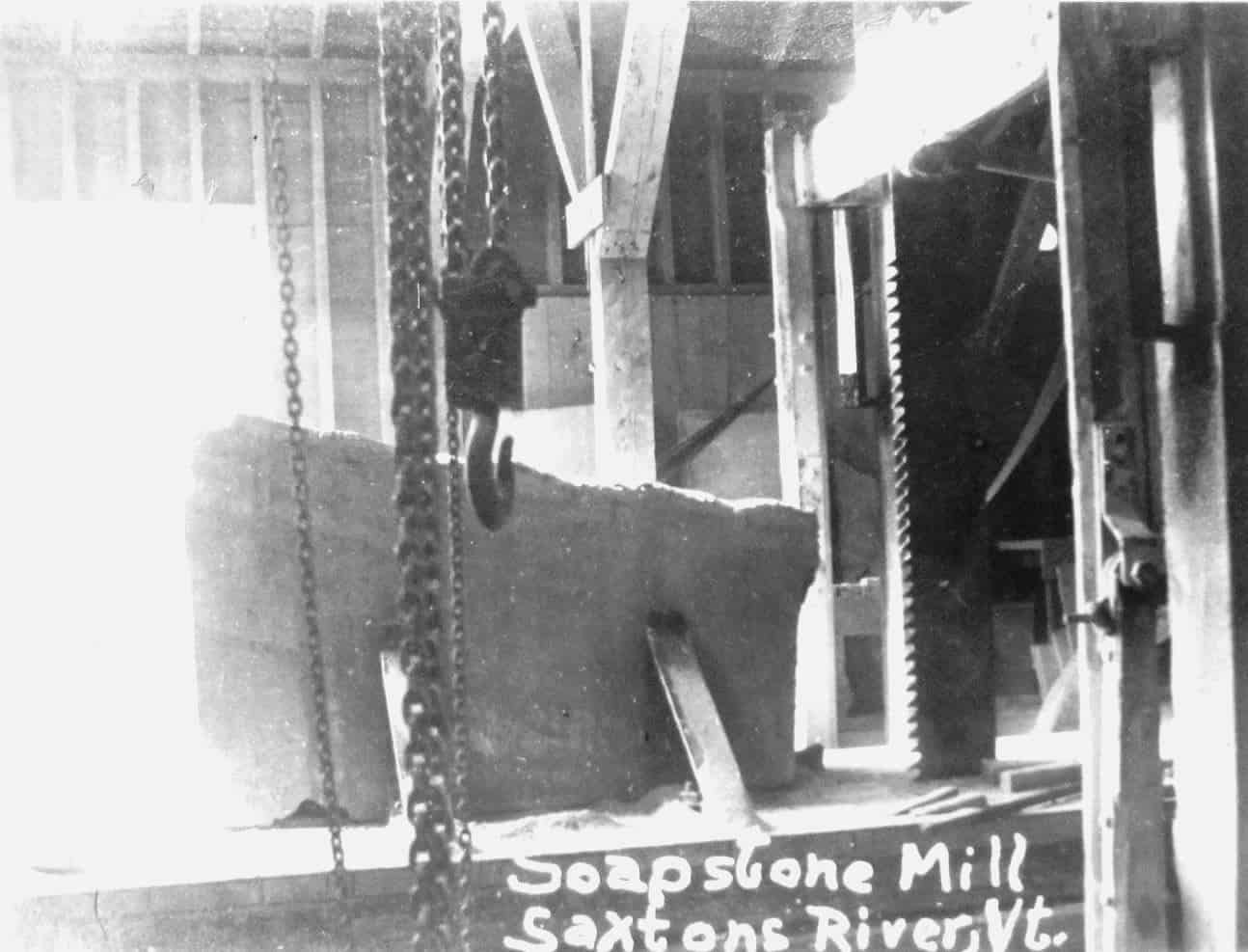

The photo with this article shows the up and down saw at Saxtons River soapstone mill. Union Soapstone in Chester had two of these up and down saws.

Instead of an old saying, I offer a Crazy Lady story from 1974.

Crazy Lady

Crazy Lady ran an antiques shop on Route 5. Many dealers, myself included, stopped to do business. Some days she seemed fine, other days she was just plain nuts.

In front of her shop, out in the weather, she had rows of old chairs, broken yarn winders, and such, to entice customers to stop. I don’t remember the details now, but Randy of Claremont stopped with his large box truck to complete a deal he had made the day before. Crazy Lady went nuts, chasing Randy out of her shop.

She was beating on the side of Randy’s truck when he made his escape. Randy backed up, and then drove over her display of chairs as he left!